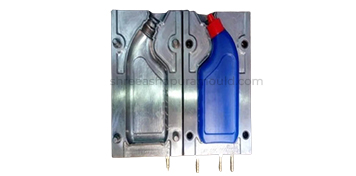

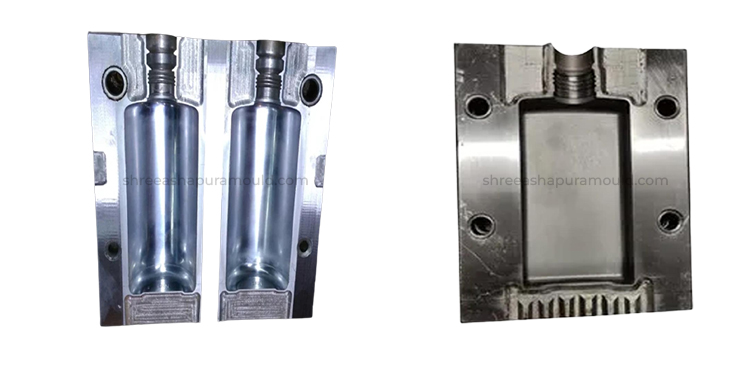

High-Quality Blow Moulds & HDPE Blow Moulds for Durable Container Solutions

At Shree Ashapura Mould, we specialize in manufacturing Blow Moulds and HDPE Blow Moulds that cater to a wide range of packaging applications. Our moulds are engineered for precision, consistent wall thickness, and long-lasting durability, supporting efficient bottle and container production across various industries.

Why Choose Shree Ashapura Mould for Blow Moulds?

- Precision Engineering – Designed for uniform distribution and consistent container shape

- HDPE Expertise – Specialized moulds for High-Density Polyethylene (HDPE) bottles and containers

- Versatile Designs – Compatible with single- and multi-cavity blow moulding systems

- Durable Construction – Manufactured from high-grade tool steel for superior lifespan and performance

Our Blow Mould Capabilities

- 1 to 4 cavity moulds for small- and medium-scale production

- Container volumes ranging from 50ml to 20L+

- Moulds for round, square, oval, and custom-shaped bottles

- Support for handle-type containers, jerry cans, and dairy bottles

- High-polish cavities for glossy surface finishes

- Moulds suitable for linear and rotary blow moulding machines

Industries We Serve

- Pharmaceutical & Healthcare – Bottles for syrups, tablets, and disinfectants

- FMCG & Retail – Containers for shampoos, body lotions, and detergents

- Industrial Chemicals – HDPE jerry cans and bottles for oils, lubricants, and solvents

- Agro & Pesticides – Safe and durable packaging for fertilizers and pesticides

- Food & Beverages – Blow moulds for juice, milk, yogurt, and edible oil bottles

High-Performance Features of Our Moulds

- Precision Thread Finish – Ensures tight sealing and compatibility with standard caps

- Uniform Wall Thickness – For enhanced durability and aesthetic appeal

- Optimized Cooling Channels – Reduces cycle time and increases output

- Corrosion-Resistant Coatings – Ensures long mould life even in heavy-duty use

- Interchangeable Inserts – Supports multiple neck sizes or designs within the same mould base

Reliable After-Sales Service & Support

- On-site mould setup and testing

- Operator training and process consultation

- Quick turnaround on spare parts and repairs

- Dedicated support team for on-call maintenance and service

Get the Best Blow Mould & HDPE Blow Mould Solutions from Shree Ashapura Mould

If you're looking for high-quality moulds for HDPE or PET blow moulding, trust Shree Ashapura Mould to deliver reliable, customizable, and production-ready tools. Our moulds are built to help you reduce downtime, increase speed, and maintain consistent product quality.

Contact us now to explore our moulding capabilities and get the right solution for your packaging line.

Frequently Asked Questions

1. What is the difference between Blow Mould and HDPE Blow Mould?

Blow moulds are used to form hollow plastic products, while HDPE blow moulds are specifically designed for High-Density Polyethylene containers, often used for chemicals, dairy, and lubricants.

2. Which materials are compatible with your blow moulds?

We design moulds for PET, HDPE, LDPE, and PP, depending on your product and application.

3. Can you design custom shapes or handles in HDPE containers?

Yes, we specialize in custom blow moulds, including handle bottles, jerry cans, and unique branding features.

4. What kind of machines are your moulds compatible with?

Our moulds are compatible with extrusion blow moulding, injection blow moulding, and stretch blow moulding machines from leading manufacturers.

5. Do you offer sample testing or mould trials?

Absolutely. We provide sample testing and support during trial runs to ensure the mould matches your machine and performance expectations.